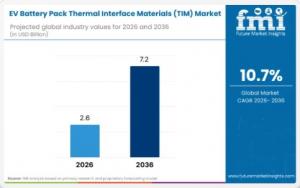

Global EV Battery Pack Thermal Interface Materials Market Forecast to USD 2.6B in 2026, USD 7.2B by 2036 with 10.7% CAGR

Market expands on EV growth, stricter safety standards, and evolving battery architectures driving advanced thermal solutions for electrification.

NEWARK, DE, UNITED STATES, February 6, 2026 /EINPresswire.com/ -- The EV battery pack thermal interface materials (TIM) market is projected to grow significantly over the next decade, responding to rapidly expanding electric vehicle (EV) production, increasingly sophisticated battery architectures, and heightened safety and performance standards that elevate thermal management from a component focus to a system-critical requirement. The market’s core role in managing heat, enhancing reliability, and supporting advanced charging architectures reflects the broader evolution of electrification in automotive and energy sectors.

Market Overview: Who, What, Where, and When

According to Future Market Insights, global demand for thermal interface materials used in EV battery packs is forecast to grow from approximately USD 2.6 billion in 2026 to USD 7.2 billion by 2036, at a compound annual growth rate (CAGR) of around 10.7% over the period. This expansion is underpinned by ongoing shifts toward high-energy battery platforms, increased fast-charging adoption, and stringent safety standards that prioritize effective heat dissipation and fire resistance in battery systems.

Where: The market’s growth is geographically broad, with demand led by key EV manufacturing hubs in East Asia (notably China), North America, and Western Europe. Emerging regions, including Brazil and other rapidly electrifying markets, are also contributing to adoption curves as battery manufacturing scales regionally.

When: The forecast timeline spans 2026 through 2036, reflecting long-term strategic shifts in electrification, materials science, and regulatory frameworks shaping vehicle safety certification and battery thermal controls.

Market Context and Why It Matters

The explosive growth of electric vehicles, with EV battery demand surpassing 950 GWh in 2024, has made thermal management solutions a central technology enabler rather than an optional add-on. High-density battery cells and faster charging profiles generate intense heat loads, making efficient thermal interface solutions essential to maintain performance, longevity, and compliance with mandatory safety standards.

Industry analysts note that TIMs now influence both safety compliance and operational durability, particularly as new Cell-to-Pack (CTP) and Cell-to-Chassis (CTC) battery architectures reduce tolerances and elevate thermal stress across pack assemblies. This architectural evolution is increasing demand for TIMs capable of balancing conductivity with mechanical resilience and integration simplicity in automated production environments.

Key Drivers and Trends

1. EV Production Scaling:

Accelerating global EV adoption, paired with local manufacturing incentives and safety regulations, continues to drive material intensification within battery packs.

2. Regulatory and Safety Standards:

Advanced standards, including fire resistance and thermal runaway mitigation measures, are expanding the role of TIMs from simple heat transfer enhancers to critical safety components required for regulatory compliance.

3. Diverse Material Innovation:

Market activity underscores significant progress in thermally conductive gap fillers, silicone elastomers, and adhesives that blend thermal transfer with structural characteristics to meet multi-axis performance criteria.

4. Automated Manufacturing Integration:

Gap fillers and pastes, which accounted for a leading share of material formats due to ease of automated application and superior surface conformity, continue gaining adoption across automated battery assembly lines.

Challenges and Market Restraints

Despite strong growth prospects, the EV TIM market faces several headwinds:

• Cost sensitivity: Advanced TIMs with specialized formulations often command significant price premiums compared with conventional materials.

• Supply chain uncertainty: Raw material volatility and quality control complexities expose production to geopolitical risks and logistics pressures.

• Performance trade-offs: Achieving peak thermal performance without compromising mechanical flexibility or lifecycle stability remains a complex materials science challenge.

Segmentation and Industry Structure

The EV battery TIM market’s segmentation demonstrates variation in both material form and chemistry:

• Gap fillers & pastes: Representing the largest share given their adaptability in high-throughput battery builds.

• Silicone-based systems: Widely preferred for balancing thermal conductivity with mechanical durability across temperature cycles.

• Additional segments include pads/sheets, phase change materials, greases, and specialized composites tailored to performance constraints.

Competitive Landscape

Leading global material suppliers are actively innovating to address diversified EV battery requirements:

• 3M Company has emphasized ceramic fiber matrices capable of withstanding extreme thermal events.

• Henkel AG & Co. KGaA expanded adhesive solutions optimized for automated production.

• Parker Hannifin’s LORD division positioned advanced gap fillers with enhanced reworkability and recycling considerations.

Other major participants include Dow Inc., Shin-Etsu Chemical, Wacker Chemie AG, Momentive Performance Materials, Saint-Gobain Performance Plastics, and SGL Carbon SE, collectively propelling innovation across chemistry domains.

Future Outlook and Strategic Significance

The EV TIM market’s projected trajectory underscores broad industry transformation: as electrification deepens, materials that ensure safe, reliable, and scalable thermal management will become indispensable components of next-generation battery systems. Strategic investments, coupled with regulatory harmonization and expanding manufacturing ecosystems, signal that demand for advanced TIM solutions will remain strong throughout the forecast period.

Request for Sample Report | Customize Report |purchase Full Report – https://www.futuremarketinsights.com/reports/sample/rep-gb-31868

Explore More Related Studies Published by FMI Research:

Railway Traction Inverter Market https://www.futuremarketinsights.com/reports/railway-traction-inverter-market

Park Assist System Market https://www.futuremarketinsights.com/reports/park-assist-system-market

Automotive Connectivity Market https://www.futuremarketinsights.com/reports/automotive-connectivity-market

About Future Market Insights (FMI)

Future Market Insights, Inc. (FMI) is an ESOMAR-certified, ISO 9001:2015 market research and consulting organization, trusted by Fortune 500 clients and global enterprises. With operations in the U.S., UK, India, and Dubai, FMI provides data-backed insights and strategic intelligence across 30+ industries and 1200 markets worldwide.

Why Choose FMI: https://www.futuremarketinsights.com/why-fmi

Sudip Saha

Future Market Insights Inc.

+1 347-918-3531

rahul.singh@futuremarketinsights.com

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.